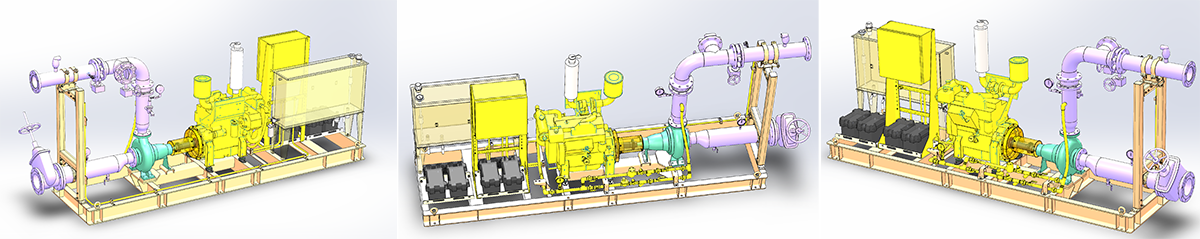

Dynapumps are providing a standalone Diesel Fire Water Pump system to tie into our client’s existing system to meet the requirements of AS2941. The skid includes a Pentair SX ISO-PRO 125x100-315 end-suction centrifugal pump, coupled via a 1410 series driveshaft with a Centa torsional coupling to a Cummins 4BTA C-130 heat exchanger cooled diesel engine. A 180L dual skin fuel tank is provided to fuel the diesel engine for up to 6 hours of run time and includes a GTS level sender wired back up to Dynapumps’ custom diesel control panel to provide a fuel level in the tank.

The suction pipework is size to restrict pipe velocities to below 2m/s to prevent any friction losses or turbulent flow entering the pump, with a Challenger gate valve, a level gauge, and a drain valve provided within this suction pipework assembly. The discharge pipework feeds back over the top of the suction, including an integral wafer check valve, gear operated butterfly valve, and a separate test line connection to meet the requirements of AS2941. Both the suction and discharge pipework are supported by Sikla SiFramo modular supports.

The entire assembly is mounted on a base frame custom designed and fabricated in-house by Dynapumps. The Diesel Fire Water Pump system will undergo testing using our in-house testing facilities to ensure compliance with the relevant Australian standards.