Fossil fuels such as natural gas and crude oil are used to create heat and electricity, manufacturing gasoline and producing various products. The oil & gas and petrochemical industry outlines firm requirements for suppliers and their technical equipment. As a prominent worldwide supplier, SEEPEX offer superior conveying technology that delivers the critical edge in this area. SEEPEX develop tailor-made pumping solutions and offer optimum technical and economical solutions for almost every application in the Oil & Gas industry.

SEEPEX pumps achieve maximum results by featuring:

SEEPEX pumps achieve maximum results by featuring:

- Low shear forces

- Self-priming pumps, no gas locking on products with a high gas yield and solids content

- Remarkably low NPSH values

- Processes highly viscous fluids

- Constant flow rate over varying discharge heads

- Pump capacity can be modified to eliminate flow control valves

- High operational safety

- Ease of maintenance

- Low energy consumption

- Designed in accordance with API 676 3rd Edition

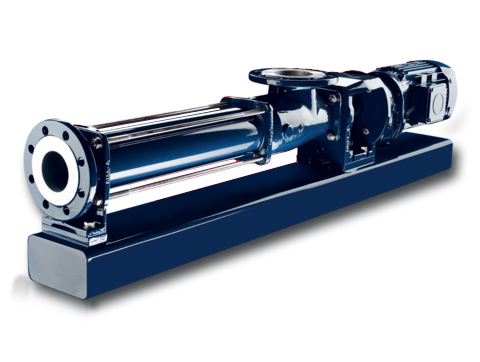

SEEPEX progressive cavity pumps from the BNA range are specifically designed to fulfill demanding requirements identified from the Oil & Gas Industry, posing the complete compliance with API 676 and API 682, corrosion resistance and rugged, heavy-duty casting design which makes the engineering process most efficient.

The BNA progressive cavity pump will be on show at the (AOG) Australasian Oil & Gas Exhibition & Conference, Perth Convention Centre from March 13-15, at Dynapumps - Stand L26. To inquire about our SEEPEX product range and Oil & Gas solutions. Contact Dynapumps on 1300 788 579 or email sales@dynapumps.com.au.