A major soap manufacturer uses soap noodles and add pigments, fragrances, and other components to create their range of soap brands and products. Soap Noodles are saponified from vegetable oils and animal fats to provide the raw material for varies soap manufacturers. The noodles are made using sodium hydroxide to form a salt of the fatty acids from the oils or fats.

The problem was that the customer’s initial process used Progressive Cavity (PC) pumps, but the pumps could only survive a couple of days before breakdown due to the difficult pumping application. The process contained a viscous product (100,000 cps) and used a line pressure of 435 psi (30 bar) and pumping temperature of 275°F (135°C).

The original Progressive Cavity pumps used elastomeric stators but lasted only three days before breakdown. The Progressive Cavity pump provider tried various versions of their design including a version with a metal stator, but it failed within a week.

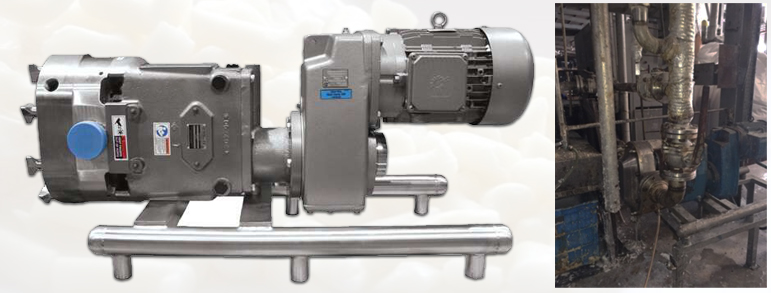

The solution was the Waukesha Cherry Burrell - Universal 2 Series pump (model 210) with Tru-Fit Adapter as it featured the heavy-duty design required to handle the unique high-pressure process. U2 pumps are made with large diameter shafts, heavy-duty bearings, robust spur gears, and solid metal rotors to handle high torque applications.

The External Circumferential Piston (“ECP”) style rotors with large crossover clearances and ratings for high temperatures were able to pump the product without issue.

From the moment the pump was installed, it has worked flawlessly. The pump was installed in 2007 and 8 years later it is still performing, only requiring replacement of the tungsten carbide seals.