Applications with evaporation, deaeration or other low inlet pressure situations can cause pumps to lose their production efficiency and cause damaging cavitation. The problem is amplified for high viscosity products, as the flow to the pump inlet is more restricted from the increase in frictional pressure loss. This can leave producers struggling to obtain the flow rates and capacities required to meet production targets, increase downtime and maintenance costs. One processed cheese manufacturer had tried several pumps but was still not getting the desired results.

A Challenging Application

A good example of this problem is an application for sheet formed, sliced processed cheese. The processor wanted to reach required productivity levels while maintaining the quality of the cheese with a consistent appearance. Prior to entering the sheet former, the cheese passed through a deaeration vessel to remove air that could form visually unappealing bubbles in the sheets of cheese. With the high viscosity of the cheese and vacuum within the deaeration vessel, this was going to be a challenging pumping application.

Pump Solution Still Created Issues

The processor had tried different lobe pumps and an external circumferential piston (ECP) pump, but none could provide the correct flow without cavitation because of the low inlet pressure. Eventually, a rubber rotor lobe pump was applied that offered a reasonable solution. This type of pump helped with efficiency and pulled a relatively good vacuum, but flow was still sacrificed.

The pump configuration also meant that there was running contact inside the unit with potential for wear on the lobes. This presented the risk of rubber from the lobes entering the cheese. Furthermore, the configuration did not allow for clean-in-place (CIP), so the pump had to be stripped down and manually cleaned every 72 hours. This had detrimental results on productivity and the producer continued to look for a better solution.

Twin Screw Pump Improved Results

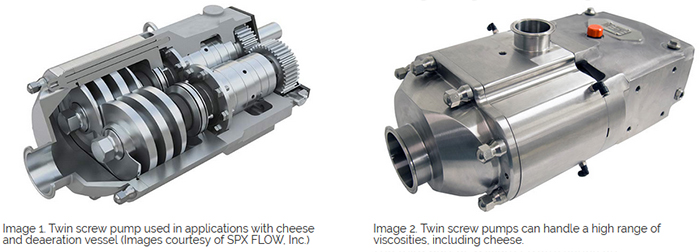

Twin screw technology is designed to handle low inlet pressure applications. Rotors or lobes within a pump cut across its inlet, which can increase the inlet pressure required for the pump to run. Rather than blocking the inlet, however, the screws in a twin screw pump create an auger effect that helps the fluid into the pumping chamber. Using nongalling internal materials and precision engineering, the pumps can also be constructed with tight internal tolerances to create greater suction and increased pumping efficiency.

The cheese manufacturer tried placing a twin screw pump in the processing line. This resulted in a more than 10 percent increase in flow and an increase in vacuum pull from 15 to 17 inches of mercury (inHg). The noncontacting-style pump not only offered an increase in production capacity, but also reduced the risk of contamination created by the contacting lobe pump.

It further offered the capability for CIP, removing the need for frequent manual cleaning and saving around two hours of cleaning time per cleaning cycle. This better optimized production time and reduced maintenance overhead. With less downtime and an increase in flow capacity from around 72 gallons per minute (gpm) to 80 gpm, the twin screw pump improved productivity.

Following the trial in the initial facility, the cheese manufacturer has since installed the twin screw pumps in two additional plants. Each plant has two identical systems that run in parallel (two pumps per plant).

Customized to Exact Requirements

One supplier worked in partnership with this customer to achieve the improved results for the processed cheese production. The pumps supplied were customized to specific needs for the processing line. As the flowing cheese is hot, around 150 F, it has the potential to solidify around the pump inlet and reduce the amount of open area for flow into the pump. To reduce bridging at the inlet and enable easier flow into the pump, the pump was produced with a rectangular flange inlet. To assist with cooling the product on the discharge side of the pump, which affected cleaning efficiency, the outlet was also customized into a tapered form to make the transition of the product smoother and prevent buildup of solidified cheese.

Additional Advantages

The twin screw pumps are compliant with 3-A sanitary standards, United States Department of Agriculture (USDA), International Organization for Standardization (ISO) 9001:2008 and European Conformity (CE) standards. The pumps have high strength bearings that maintain axial loads and heavy-duty shafts for increased torque and reliability. No bearings are used in the product zone and front-loaded access to the product side seals simplifies routine maintenance tasks.

The pumps produce minimal noise, reduce pressure fluctuations in the process and have bi-directional flow capability. They can handle a wide range of fluid viscosities, including the highly viscous processed cheese and thin CIP fluids, which may reduce the total number of pumps, valves and controls required for a process. The use of the nongalling alloy inside the pump not only means tight tolerances can be produced to increase flow efficiency, but also helps further protect the pump from potential damage. Unlike other pump configurations, the pump will not gall, seize up or cause catastrophic damage.

Conclusion

Hygienic twin screw pumps can offer a return on investment for challenging food processes. The tight internal tolerances enabled using special alloys means the pumps are much less likely to cavitate at low inlet pressures and less prone to slippage. For this processed cheese producer, the twin screw pumps proved to be a good option. This type of pump was shown to be a reliable, easily cleanable solution that increased productivity and helped produce the quality of cheese that was required.