A recent project has been completed in the Russian oilfield in north Oshkotyn. The Russian oil company was supplied with two Leistritz multiphase units. ‘The units are being used in a permafrost region. ‘It was not just the very high-temperature variations ranging from -40°C to +50°C, which presents a big challenge for these pumps; it was also the delivery to this location itself, which proved a remarkable logistical achievement.

A recent project has been completed in the Russian oilfield in north Oshkotyn. The Russian oil company was supplied with two Leistritz multiphase units. ‘The units are being used in a permafrost region. ‘It was not just the very high-temperature variations ranging from -40°C to +50°C, which presents a big challenge for these pumps; it was also the delivery to this location itself, which proved a remarkable logistical achievement.

‘The oilfields are situated in an area, which is only accessible in the winter months from October until March. During the summer months, it changes to a swamp. Thus, the only solution was delivery by air.’ The pumps were flown to the operation site by the most significant type of helicopter in the world.

The multiphase pumps extract crude oil and raw gas with a gas concentration (GVF) of 97% from the boreholes and collecting pipes to centralised treatment plants. They're used for handling the untreated mixture of gas and liquid with a capacity of up to 5,000m3/h and a differential pressure of up to 100bar. The conventional approach is to separate the gas from the fluid (a hydrocarbon with water) and extract both phases in separate pipelines to a collecting point for the first separation process before feeding them into long-distance pipelines. ‘This is very costly, needing separators, compressors, fluid pumps, heaters or individual pipes. ‘This can, however, be avoided by using the economic multiphase pump. Another bonus is that it can accelerate the transport of the multiphase mixture to a central treatment plant via just one pipeline.’

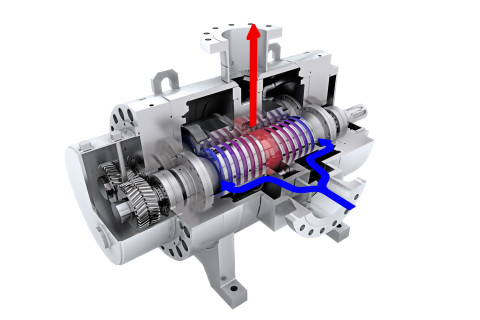

From a technological point of view, the multiphase pumps are based on twin screw double volute pumps. These self-priming pumps consist of a dual flow casing and thus are axial hydraulically balanced. The option of an RPM regulator via a frequency converter drive covers a broad spectrum of possible operations. The pump and all other equipment, including the required controls and electric motors, are assembled on a base frame in a skid-construction. The liquid management system of Leistritz ensures operation up to 100% GVF. One essential aspect has to be noted, by using multiphase pumps the flaring of gas can be avoided to a large extent. By transporting the entire gas and liquid mixture in one pump, it not only reduces the damage to the environment but also provides more efficient use of energy resources. The twin screw, double volute pumps utilised here are suited for the matter with a viscosity range of up to 150,000cSt. They can handle flow rates of up to 2,000m³ and employ a differential pressure of maximum 150bar.

Leistritz specialise in multiphase technology with nine decades of experience in manufacturing and design. To take advantage of multiphase for your application, please contact one of our Pump Specialists at Dynapumps on 1300 788 579 or email sales@dynapumps.com.au.