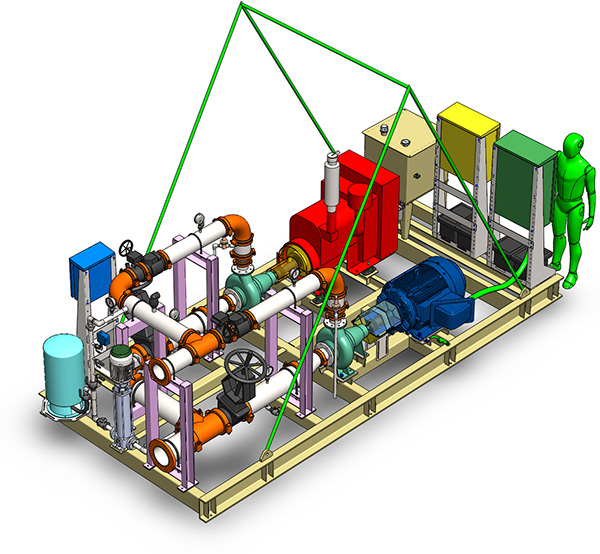

A Lithium Project commissioned a fire water system equipped with ISO-PRO pumps to produce flow rates of 40L/s to meet the site fire water demands. The Electric Fire Water Pump is powered using the 90kW 2P electric motor through a flexible disc coupling. The Diesel Fire Water Pump is powered by a 100kW diesel engine, with a driveshaft utilising a torsional coupling to transfer the power from the engine to the pump.

Each pump shares a common suction tie-in point, which then forks into individual suction lines. Each suction line contains a gate valve, drain valve, and compound pressure gauge. The pumps have their discharge lines, which eventually manifold into a common discharge, with each discharge line containing a casing relief valve, check valve, butterfly valve, and pressure gauge. The suction and discharge pipework utilises grooved connections throughout for straightforward assembly and maintenance.

The entire assembly rests on a custom-designed, fabricated galvanised base frame, plus the fuel tanks are completed in-house by Dynapumps. The fuel tank size is for AS2941 for 6 hours of the run time of the diesel engine. Our electrical department is responsible for designing, wiring, and testing the diesel and jockey pump control panels. While the electric pump panel design, wiring and testing were done by a supplier to comply with AS61439.