Problem Statement

An issue at a local council started with the inability to remove potentially contaminated water from their Water Filtration Plants treated water well. It meant that any untreated or out of spec water had to be pumping into the distribution system. The clear water well is below ground, and the configuration of their high-lift pump pipework could not enable the connection of an offtake to waste. Not having the ability to discharge filtered water that does not meet drinking water guidelines is a huge problem. It was identified within their Drinking water management system Improvement Plan as a high priority to address. For the Water Filtration Plant to continue to meet drinking-water management system standards, they needed a solution. A secondary issue was plant functionality during the winter months. Wintertime flows are significantly lower than summer flows requiring the existing high-lift pumps to be throttled back to an inefficient point.

The Solution

The Solution

The team discussed various options and brought about the idea of utilising a permanent pump setup. A fourth high-lift pump had always been the plan for installation (to supply to the town’s distribution system) but never thought of for a second purpose (to empty the wet well). The ability to discharge water from the wet well to waste improved our business case significantly. An investigation was done to determine the most cost-effective options. The system had to enable the pump to either pump to a discharge pipe or into the distribution system. This could not be achieved by a single-headed pump due to the limited manifold space. The result was a dual discharge pump. This allowed the Council to waste non-compliant water from their clear water well and covered the wintertime flow needs giving us improved plant functionality. A fourth pump also gave them contingency in the event of the other pump failures.

Pump Design Specification

Pump Design Specification

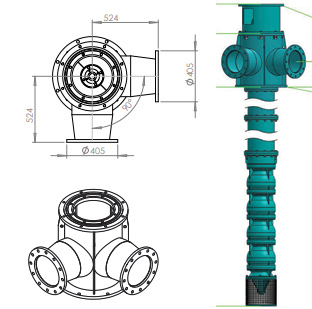

A design with flow requirements was drawn within the Council and sent to Dynapumps for the custom pump to be engineered and meet specifications. The pump has four stages, with stainless steel bowls and open stainless steel impellers. The column is a flanged 300mm pipe with water-lubricated bearings. The pump is powered by a 110kW motor with VSD control.

Test Results

The pump was bench tested before installation to ensure required flows were met. The test results mirrored the commissioning results minus 5%.

Commissioned Pump

The commissioned pump meets the Councils required flow rates for wintertime pumping between 110 and 160L/s. The waste discharge flow rates meet with the motor speed at 25Hz. The pump now gives the Council the ability to empty our clear water well in five hours if needed.