In times of unpredictable oil prices, tank terminals are experiencing more demand as there is a growing need for refined oil and crude products. Using an efficient pumping system can contribute to a flexible and low-cost operation for tank terminals in the long run. Screw pumps are used to a large extent to transport stored oil products, while twin-screw pumps offer versatility and several benefits in operating a tank terminal, compared to using centrifugal pumps for the procedure.

The biggest benefit is that oil products of varied thickness and content, with the pressure and suction conditions can be pumped without any issue with the single pump in operation. As tank terminals are now built even larger and requiring longer pipes, centrifugal pumps are now a restrictive factor. In regards to twin-screw pumps, they offer a continuous capacity over a wide viscidness and pressure range. With the recent market developments, Leistritz have answered the demands by releasing the new L4NC series of compact and cost-efficient rotary positive displacement pumps.

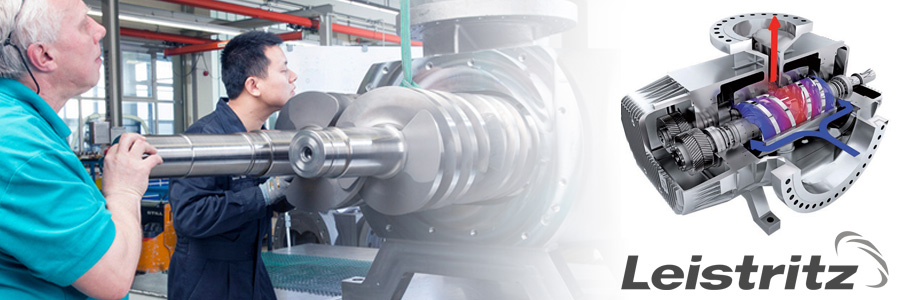

The L4NC series is specifically designed for tank terminal applications, covering an extensive range of areas and can also be utilised in the chemical petrochemical and shipping industry as loading or unloading, stripping and booster pump. The new series is an improvement over the previous Leistritz twin screw pump models, which have been used for many decades. The compact L4NC design is considered by and act in accordance with the API 676 3rd Edition. The pump series comprise of seven sizes, each with four pitch variations, providing an optimal selection per application.

Leistritz use the latest in manufacturing technology to form the spindles from one piece of metal, a casted steel casing and integrated pump liner. The end product creates low shaft deflection, which result in high efficiency and extensive service life for the shaft seals and bearings. The compact spindle design offers the best lubrication for the timing gears and bearings while achieving high performance values regardless of pump size. The drive spindle and idler spindle are sealed by balanced or unbalanced, single acting component or API cartridge seals for simple maintenance for the user. The range of L4NC pump sizes cover a flow rate of up to 5000 m³/h and pressure levels up to 20 bar for several fluids such as bitumen, crude oil, light and heavy fuel oil or other petrochemical substances.

Leistritz are at the forefront of twin-screw pump technology offering the latest in efficiency, compact design and reduced costs for all end users and applications. For more information and expert advice, please contact our Leistritz Specialist, Mark Wilkins on +61 (0)8 9424 2047 or email mark.wilkins@dynapumps.com.au.