Correct pump selection is vital to run pumps efficiently and effectively for your application. By selecting the correct pump you can potentially save your business thousands of dollars. Dynapumps recently replaced the liquid ring pumps at Austral Bricks in Melbourne with Rotary vane pumps which were much better suited for their application thus leading to a AU$23,390 saving in their overall costs.

The Application

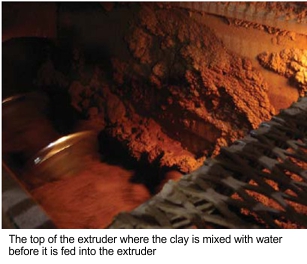

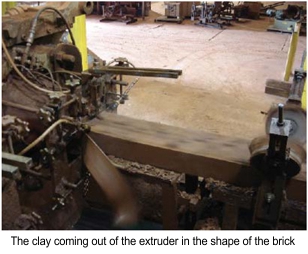

Vacuum pumps can be used for the drying of bricks. Vacuum is applied to the extruder which reduces the amount of moisture in the clay when it is formed into the brick shape. The vacuum level is generally -90kpa and flow rates of around 600m3/hr.

Vacuum pumps can be used for the drying of bricks. Vacuum is applied to the extruder which reduces the amount of moisture in the clay when it is formed into the brick shape. The vacuum level is generally -90kpa and flow rates of around 600m3/hr.

Liquid Ring vacuum pumps are traditionally used throughout the industry but the increase in power and water costs have caused some operators to look for a better solution. Liquid Ring pumps are used because of the high water vapour content and dusty conditions. However the disadvantages are that in summer the seal water temperature in the pump is higher and less vacuum can be achieved which means the bricks take longer to dry due to the amount of moisture still left in the clay. Also the maintenance costs of liquid ring pumps are very high.

Our Solution

Our Solution

Dynapumps have an understanding of many different types of vacuum pumps and can therefore find the optimum selection for an application. The solution came through the selection of the Rotary Vane pump. This pump is designed so it will be able to handle a large amount of water vapour and with the inclusion of an inlet separator and filter the dust is eliminated. The vacuum level is also increased from -90kpa to around -96kpa. This level is kept steady all year round no matter what the climate is. This also means a saving in drying time which in turn speeds up production. All together the savings in time and money means this solution is the way of the future.

Cost Savings

The previous pumps had running costs of just below AUD$ 39,400/year. See the below table* for the comparative analysis between the liquid ring pump and rotary vane pump at Austral Brick.

|

|

Measure Unit

|

Liquid Ring

Pump

|

Rotary Vane

Pump

|

Calculus

|

|

Working hours per year

|

h/year

|

8760

|

8760

|

A

|

|

Vacuum pump capacity at 80 mbar

|

m3/hr

|

450

|

450

|

|

|

Pump oil quantity

|

litres

|

0

|

19

|

|

|

Oil consumption

|

litres/ month

|

0

|

19

|

|

|

Oil cost

|

AUD/ltr

|

0

|

5

|

|

|

Water consumption

|

m3/hr

|

2.1

|

0

|

B

|

|

Water Cost

|

AUD/ m3

|

1

|

0

|

C

|

|

Water Cost every 8760 hours

|

AUD/year

|

18396

|

0

|

X=AxBxC

|

|

Manpower

|

Hr/day

|

.5

|

0.5

|

D

|

|

Manpower costs

|

AUD/hr

|

50

|

50

|

E

|

|

Manpower costs every 8760 hours

|

AUD/year

|

9125

|

9125

|

Y=DxExA/24

|

|

Energy costs

|

AUD/kWh

|

0.06

|

0.06

|

F

|

|

Power consumption of the cool tower

|

kW

|

0.6

|

0

|

G

|

|

Power consumption of pumps

|

kW

|

22

|

15

|

H

|

|

Energy costs every 8760 hours

|

AUD/year

|

11878.56

|

7884

|

Z=AxFx(G+H)

|

|

Running costs (water, manpower, energy)

|

AUD/year

|

39399.56

|

17009

|

K=X+Y+Z

|

|

Saving every 8760 hours

|

AUD/year

|

0

|

22390.56

|

|

|

Spares and Maintenance costs every 8760

hours

|

AUD/year

|

6000

|

5000

|

|

|

Total saving every 8760 hours

|

AUD/year

|

0

|

23390.56

|

|

*Courtesy of Dynapumps, some figures may be an approximate value.