Removing groundwater is a continuous problem. Most mines use large centrifugal pumps to pump it out. Almost 90% of these pumps incorporate packings and 10% use mechanical seals. Since the slurries being pumped are abrasive, the packing can wear out relatively quickly without a reliable seal flush system.

The small pumps used to deliver clean water to the seal area of a centrifugal pump must operate at a pressure high enough to overcome pressure inside the stuffing box. When a mine is new, this pressure may be relatively low. But the deeper the mine or the further the dirty water and sludge must be pumped, the higher the required operating pressure of the large multi-stage centrifugal pumps. Pressure in the stuffing box can exceed 600 psi (40 bar).

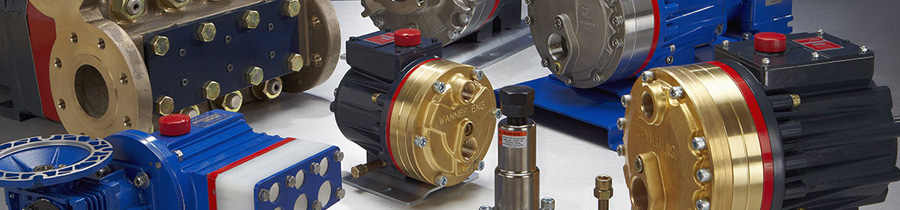

Seal flushing is a critical operation, but the conventional piston or plunger pumps sometimes used to deliver clean water for seal flushing, are not always able to do so effectively. Mine engineers in the US and elsewhere have reported two particular problems – pulsation and seal wear. Free from these limitations, the Hydra-Cell seal-less pump has increasingly been preferred for seal flushing.

Short sequential flexing strokes provide the pumping action of multiple diaphragms in the Hydra-Cell pump. Pulsation is minimal. And there is no seal wear because the pump has no dynamic seals. It can provide steady high-pressure clean water flushing for long periods with no loss of performance.

By contrast, conventional seal cleaning pumps are themselves seal-reliant. Performance will fall off as their seals wear. Moreover, the suction and discharge strokes of pistons in these pumps are relatively long. During the inlet stroke, when pressure drops sharply though for a brief moment, contaminate may be allowed to migrate into the packing area of the large pump. Once this happens, its seals can quickly degenerate. Seal failure in a high-volume centrifugal pump is likely to be seriously expensive in terms of downtime and pump repair costs.

Many Hydra-Cell pumps are in successful use for seal washing, nor is this operation confined to groundwater transfer. One reported application is in copper mining. After the mineral has been extracted, the residual material or tailings are mixed with water and conveyed to a centrifugal separator. Large centrifugal pumps made for handling slurries take the slurry from the separator and deliver it to evaporative ponds that can be several miles away. As time goes on, new ponds are dug progressively further from the mine site and the hydraulic pressure needed to move the heavy and abrasive slurry increases to 600 psi and beyond. Consistent, reliable seal cleaning is essential in these circumstances to avoid costly slurry pump failures. Hydra-Cell pumps have proved themselves fully equal to the task.

Dynapumps can help you with our extensive Hydra-Cell product knowledge, installation and all solutions for the mining industry. Contact Dynapumps on 1300 788 579 or email sales@dynapumps.com.au.