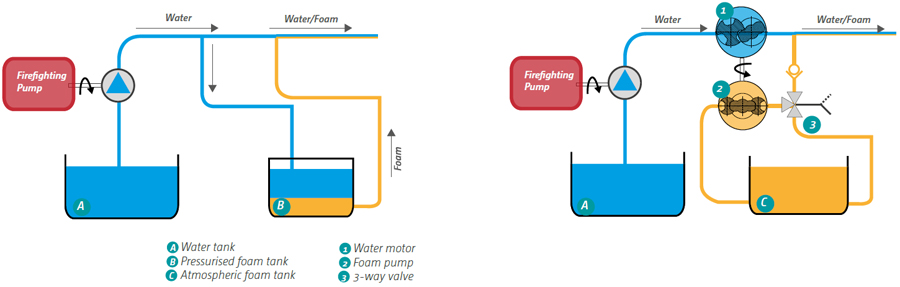

The Leistritz L23NG Proportioning Systems produce extinguishing foam in Fire Fighting plants, by mixing foam concentrate with water. The operation is self-powered as it uses the energy from the available water in pressure.

The Leistritz L23NG Proportioning Systems produce extinguishing foam in Fire Fighting plants, by mixing foam concentrate with water. The operation is self-powered as it uses the energy from the available water in pressure.

The speed of the water motor is proportional to the water flow Qw. The flow of AFFF concentrate Qf driven by the foam concentrate injection pump is proportional to the speed, thus to the water flow.

By acting on the 3-way valve it is possible either to actually inject the foam concentrate into the water flow (normal functioning), or to let the foam concentrate recirculate in its tank (simulated functioning). The required percentage of the foam concentrate in the foam solution is obtained with a proper selection of the unit capacities of both hydraulic motor and injection pump.

Traditionally a liquid displacement system is used, the water coming from the water line is used to pressurise the foam in the tank and to inject it in the water line.This solution has four major critical points:

- The system has to be calibrated

- It is sensitive to the changes of water pressure and foam viscosity.

- It cannot be tested without consuming foam

- As the foam tank is pressurised cannot be easily refilled.

Furthermore, these traditional systems cannot easily handle highly-viscous foams like alcohol resistant foams, which are applied when the fire comes from fuels. The L23NG Leistritz solution uses a combination of two screw pumps.

The Leistritz solution

The water motor and the injection pump are both derived from the Leistritz screw pumps, respectively from the series L2NG and L3MF. The two pumps, together with the 3-way valve, the injection piping and the non-return valve, are assembled on a common base plate and are fully interconnected.

The advantage with the Leistritz L23NG is that it can solve the critical points of the traditional solution, in particular:

- The system is intrinsically calibrated - the required percentage of the foam concentrate in the foam solution is obtained with a proper selection of the unit capacities of both hydraulic motor and injection pump.

- It is insensitive to the changes of water pressure and foam viscosity.

- As the foam tank is connected to the water line with a 3-way valve, setting it to recirculation is possible in order to test the system only with water (without consuming foam).

- The foam tank is atmospheric and therefore easily refillable.

Leistritz are at the forefront of screw pump technology offering the latest in efficiency, compact design and reduced costs for all end users and applications. For more information and expert advice, please contact our Leistritz Specialist, Mark Wilkins on +61 (0)8 9424 2047 or email mark.wilkins@dynapumps.com.au.